The spherical bearing for bridge consists of top plate, base plate, spherical liner plate, and two PTFE plates. The concave spherical surface of the base plate corresponds to the convex spherical surface of the top plate. The PTFE plate between the two spherical surfaces is employed to realize the rotation of the beam end. The top plate and the other PTFE plate construct the second sliding surface, realizing expansion and contraction, and displacement of the beam body caused by the factors such as temperature difference.

The spherical bearing for bridge consists of top plate, base plate, spherical liner plate, and two PTFE plates. The concave spherical surface of the base plate corresponds to the convex spherical surface of the top plate. The PTFE plate between the two spherical surfaces is employed to realize the rotation of the beam end. The top plate and the other PTFE plate construct the second sliding surface, realizing expansion and contraction, and displacement of the beam body caused by the factors such as temperature difference.

Features

Features

The spherical bridge bearing is characterized by reliable and uniform force transmission, enabling powerful bearing capacity, large horizontal displacement, and big rotation angle of the spherical bearing. So, this bridge construction material is suitable for wide bridge and curved bridge. Since the pressure bearing parts are made of the durable material rather than rubber, the performance will not be affected by the low temperature brittleness of the rubber, making this product particularly suitable for cold regions.

Installation

1. Unless approved by the designer, the spherical bearing for bridge shall not be used on the supporting part for the beam body and the pier constructed with the concrete lower than Grade C35.

2. Installation of the plate and anchor bolt. The wedge block shall be used to adjust the levelness of the base plate. The surface of the base plate is generally 20 to 50mm above pier surface. Upon the confirmation of the central line at horizontal and vertical direction, the epoxy mortar shall be poured for anchor bolt fixation and bearing bed construction.

3. If necessary, the bridge bearing can be welded to the embedded steel plate of the beam and the pier. Special attention shall be paid during welding to avoid damage to the bearing or the concrete.

4. The height of the spherical bearing shall be in compliance with the drawing, ensuring optimal surface levelness. The height difference of the four angles shall be controlled within 2mm.

Maintenance

Periodical maintenance shall be carried out, generally once a year.

1. Inspect whether the anchor bolt is broken and make it sure there is no crack or aging phenomenon on the seal ring.

2. Confirm if the relative displacement of the spherical bearing for bridge is uniform, recording the displacement conditions in detail.

3. Clean the garbage and dust, and carefully wipe the dust on the stainless steel with cotton waste.

4. To avoid rust, loosen the anchor bolt, clean, oil, and then fasten it.

5. Check the height variation conditions at fixed position of the spherical bearing in order to confirm the abrasion conditions of the PTFE plate. In case the height variation exceeds 3mm, dismantle the rubber seal ring and check the PTFE plate.

6. The periodical rust-proof treatment shall be conducted for the steel parts except the stainless steel sliding surface.

Horizontal Force

In addition to the excellent vertical load bearing capacity, the horizontal force in the direction vertical to the bridge of the one-way expansion bearing is 10% of the counterforce, which is the same with that of the fixed spherical bearing.

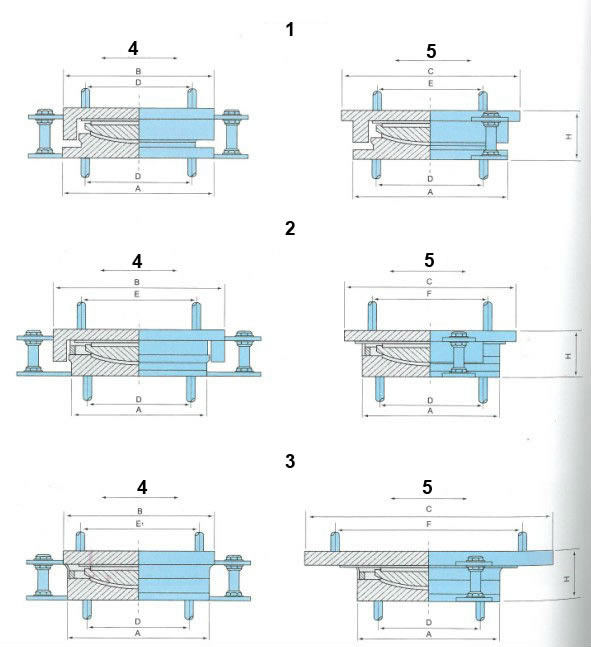

1.Fixed bearing

2.One-way expansion bearing

3.Two-way expansion bearing

4.Waterflow direction

5.Bridge direction