π type rubber fender can be mounted to a dock or a ship to counteract the collision force between the dock and the ship generated during mooring and berthing, thus preventing ships and docks from being damaged.

Features of Rubber Fender

1. The top of the marine rubber fender has a large area, offering low surface force to its contact surfaces.

2. With high energy absorption performance but low reaction force, the marine fender is ideal for use on large sized docks of 10,000 tonnages.

3. The span between the two supporting arms is adjustable. The rated compression deformation can reach 52.5%.

4. The marine rubber fender can be either vertically or horizontally installed, without a need for supporting anchor chain.

5. The UHMWPE veneer or nylon veneer for the impingement plate has a low friction coefficient of 0.07, which facilitating the berthing of a ship.

6. It is convenient and simple for installation and maintenance as well as replacement.

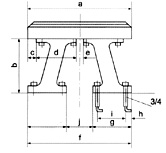

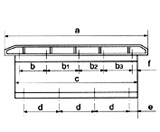

Specification of Rubber Fender

Unit: mm

| Specification | a | b | c | d | e | f | g | h | i | j |

| H600 | 1500 | 600 | 150 | 500 | 200 | 1500 | 500 | 65 | 370 | 500 |

| H800 | 1500 | 800 | 100 | 600 | 100 | 1700 | 600 | 70 | 460 | 500 |

| H1000 | 2000 | 1000 | 250 | 700 | 100 | 2000 | 700 | 75 | 550 | 600 |

| H1250 | 2500 | 1250 | 325 | 800 | 250 | 2450 | 800 | 75 | 650 | 850 |

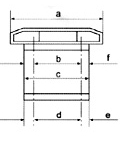

Length and Installation Size of Type π Rubber Fender

L=1500mm

| Specification | H600 | H800 | H1000 | H1250 |

| a | 1500 | 1500 | 1500 | 1500 |

| b | 700 | 700 | 700 | 700 |

| c | 1000 | 1000 | 1000 | 1000 |

| d | 700 | 700 | 700 | 700 |

| e | 150 | 150 | 150 | 150 |

| f | 150 | 150 | 150 | 150 |

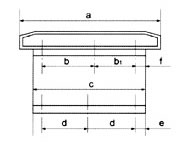

L=2000mm

| Specification | H600 | H800 | H1000 | H1250 |

| a | 2000 | 2000 | 2000 | 2000 |

| b | 650 | 650 | 650 | 650 |

| b1 | 550 | 550 | 550 | 550 |

| c | 1500 | 1500 | 1500 | 1500 |

| d | 600 | 600 | 600 | 600 |

| e | 150 | 150 | 150 | 150 |

| f | 150 | 150 | 150 | 150 |

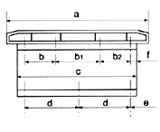

L=2500

| Specification | H600 | H800 | H1000 | H1250 |

| a | 2500 | 2500 | 2500 | 2500 |

| b | 550 | 550 | 550 | 550 |

| b1 | 600 | 600 | 600 | 600 |

| b2 | 550 | 550 | 550 | 550 |

| c | 2000 | 2000 | 2000 | 2000 |

| d | 850 | 850 | 850 | 850 |

| e | 150 | 150 | 150 | 150 |

| f | 150 | 150 | 150 | 150 |

L=3000

| Specification | H600 | H800 | H1000 | H1250 |

| a | 3000 | 3000 | 3000 | 3000 |

| b | 550 | 550 | 550 | 550 |

| b1 | 600 | 600 | 600 | 600 |

| b2 | 500 | 500 | 500 | 500 |

| b3 | 550 | 550 | 550 | 550 |

| c | 2500 | 2500 | 2500 | 2500 |

| d | 700 | 700 | 700 | 700 |

| e | 200 | 200 | 200 | 200 |

| f | 150 | 150 | 150 | 150 |

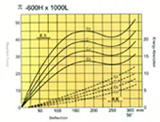

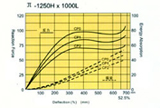

| Length(m) Performance |

High Reaction Force (C0) | Standard Type (C1) |

Low Reaction Force1C2 |

Low Reaction Force2C3 |

||||

| Reaction Force (t) |

Energy Absorption (t-m) | Reaction Force (t) |

Energy Absorption (t-m) |

Reaction Force (t) |

Energy Absorption (t-m) |

Reaction Force (t) |

Energy Absorption (t-m) |

|

| 1.0 | 46.2 | 10.6 | 39.6 | 9.1 | 33.0 | 7.6 | 26.4 | 6.0 |

| 1.5 | 69.3 | 15.9 | 59.4 | 13.6 | 49.5 | 11.3 | 39.6 | 9.1 |

| 2.0 | 92.4 | 21.2 | 79.2 | 18.1 | 66.0 | 15.1 | 52.8 | 12.1 |

| 2.5 | 115.5 | 26.5 | 99.0 | 22.7 | 82.5 | 18.9 | 66.0 | 15.1 |

| 3.0 | 138.6 | 31.8 | 118.8 | 27.2 | 99.0 | 22.7 | 79.2 | 18.1 |

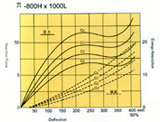

| Length(m) Performance |

High Reaction Force (C0) | Standard Type (C1) |

Low Reaction Force1C2 |

Low Reaction Force2C3 |

||||

| Reaction Force (t) |

Energy Absorption (t-m) | Reaction Force (t) |

Energy Absorption (t-m) |

Reaction Force (t) |

Energy Absorption (t-m) |

Reaction Force (t) |

Energy Absorption (t-m) |

|

| 1.0 | 61.6 | 18.8 | 52.8 | 16.1 | 44.0 | 13.4 | 35.2 | 10.8 |

| 1.5 | 92.4 | 28.2 | 79.2 | 24.2 | 66.0 | 20.2 | 52.8 | 16.1 |

| 2.0 | 123.2 | 37.6 | 105.6 | 32.3 | 88.0 | 26.9 | 70.4 | 21.5 |

| 2.5 | 154.04 | 47.0 | 132.0 | 40.3 | 110.0 | 33.6 | 88.0 | 26.9 |

| 3.0 | 184.8 | 56.4 | 158.4 | 48.4 | 132.0 | 40.3 | 105.6 | 32.3 |

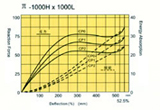

| Length(m) Performance | High Reaction Force GP0 | Standard Type GP1 | Standard Type 2 (GP2) | |||

| Reaction Force(t) | Energy Absorption (t-m) |

Reaction Force(t) | Energy Absorption (t-m) |

Reaction Force(t) | Energy Absorption (t-m) |

|

| 1.0 | 77.0 | 31.9 | 66.0 | 27.4 | 55.0 | 22.8 |

| 1.5 | 115.5 | 47.9 | 99.0 | 41.0 | 82.5 | 34.2 |

| 2.0 | 154.0 | 63.8 | 132.0 | 54.7 | 110.0 | 45.6 |

| 2.5 | 192.5 | 79.8 | 165.0 | 68.4 | 137.0 | 57.0 |

| 3.0 | 231.5 | 95.8 | 198.0 | 82.1 | 165.0 | 68.4 |

| Length(m) Performance | High Reaction Force GP0 | Standard Type GP1 | Standard Type 2 (GP2) | |||

| Reaction Force(t) | Energy Absorption (t-m) |

Reaction Force(t) | Energy Absorption (t-m) |

Reaction Force(t) | Energy Absorption (t-m) |

|

| 1.0 | 96.3 | 49.9 | 82.5 | 42.8 | 68.8 | 35.6 |

| 1.5 | 144.4 | 74.8 | 123.8 | 64.1 | 103.1 | 53.4 |

| 2.0 | 192.5 | 99.8 | 165.8 | 85.5 | 137.5 | 71.3 |

| 2.5 | 240.6 | 124.7 | 206.3 | 106.9 | 171.9 | 89.1 |

| 3.0 | 288.8 | 149.6 | 247.5 | 128.3 | 206.3 | 106.9 |

Hengsheng is a specialized rubber fender manufacturer in China. We offer various types of products such as a cylindrical rubber fender, supper cone fender, shipping facilities rubber sealed product, and rubber packing.