Characteristics of Cone Rubber Fender

1. Compared with its counterparts, our cone rubber fender offers an energy absorption increased by 100%.

2. As compared with other types of marine fender, supper cell rubber fender for instance, our supper cone fender boasts smaller sizes. To illustrate, a 800H cone fender can be used to replace a 1000H super cell fender, thus saving construction cost.

3. At berthing angles less than 10°, the fender system comes without any performance reduction.

4. The impingement plate at the front part of the fender greatly reduces the surface force to the external vessel body, thus better protecting the vessel. The surface force to vessel can be controlled in 25T/m2 or less, making the fender ideal for protecting large-sized vessels during berthing.

5. The UHMWPE veneer for the impingement plate is available to reduce the friction between the vessel and the rubber fender, allowing a friction coefficient of less than 0.2. This helps reduce the shear stress generated by the fender during vessel mooring process, thus ensuring the lifespan of the fender.

6. Fully enclosed structure for impingement plate helps ensure its strength and corrosion resistance.

7. Thanks to the veneered impingement plate, the cone rubber fender won't contact with vessels directly. Thus, the fender won't be worn, and its service life is guaranteed.

Applications of Cone Rubber Fender

1. The cone rubber fender is ideal for docks requiring a fender system with low reaction force and high energy absorption.

2. Ideal for occasions requiring a small surface force across the external panels of a ship.

3. Applicable for large sized docks like oil wharfs, container terminals and so on.

4. In addition to above, our super cone fender can be used in any places where super cell rubber fender can be used.

Comparison of Cone Rubber Fender

| Type | Designed compression deformation % | Reaction force KN | Energy absorption KN·M | Height ratio | Remark |

| 1000H super cell rubber fender | 52.5 | 445 | 195 | 1 | Standard reaction force type |

| 800H cone rubber fender | 70 | 450 | 189 | 0.8 | Standard reaction force type |

Cone Rubber Fender, ZC Type

Features

1. ZC type cone rubber fender has a large designed compression deformation and high energy absorption.

2. Easy for installation.

3. An impingement plate at the front end is available to reduce the surface force across the ship body during berthing process.

Specifications

| Specification | H | B | C | D | E | F | G | Weight |

| (mm) | Φ(mm) | Φ(mm) | Φ(mm) | Φ(mm) | #×Type | #×Φ(mm) | (kg) | |

| ZC600H | 600 | 900 | 810 | 510 | 390 | 6×M24 | 6×30 | 235 |

| ZC700H | 700 | 1050 | 945 | 595 | 455 | 6×M30 | 6×38 | 350 |

| ZC800H | 800 | 1200 | 1080 | 680 | 520 | 6×M36 | 6×44 | 540 |

| ZC900H | 900 | 1350 | 1215 | 765 | 585 | 6×M36 | 6×44 | 765 |

| ZC1000H | 1000 | 1500 | 1350 | 850 | 650 | 6×M42 | 6×50 | 1050 |

| ZC1100H | 1100 | 1650 | 1485 | 935 | 715 | 6×M42 | 6×50 | 1400 |

| ZC1150H | 1150 | 1725 | 1550 | 998 | 750 | 6×M42 | 6×50 | 1600 |

| ZC1200H | 1200 | 1800 | 1620 | 1020 | 780 | 6×M42 | 6×50 | 1950 |

| ZC1300H | 1300 | 1950 | 1755 | 1105 | 845 | 6×M48 | 6×56 | 2400 |

| ZC1400H | 1400 | 2100 | 1890 | 1190 | 930 | 6×M48 | 6×60 | 3060 |

| ZC1600H | 1600 | 2400 | 2158 | 1360 | 1040 | 6×M48 | 8×60 | 4600 |

| ZC1800H | 1800 | 2700 | 2428 | 1528 | 1170 | 6×M56 | 10×74 | 6600 |

Performance

Note: Performance Tolerance ±10%

Embedded Parts of Cone Rubber Fender

| No. | Name | Material |

| 1 | Bolt | 1Cr13 (2Cr13) |

| 1Cr18Ni9Ti | ||

| 1Cr18Ni9Ti | ||

| 2 | Washer | Q235 hot dip galvanizing |

| Q235 hot dip galvanizing | ||

| 3 | Anchor Nut | 1Cr13 (2Cr13) |

| 1Cr18Ni9Ti | ||

| 0Cr17Ni12M02 | ||

| 4 | Foot Rod (Board) | Q235 |

Specification of Embedded Parts

Connection Parts between Fender and Impingement Plate

Connection Parts between the Impingement Plate and its Veneer

| Item / Specification | Bolt | Nut | Washer | |||||||||

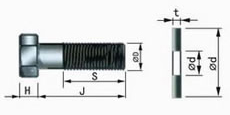

| D | J | S | H | h | a | e | D | G | d1 | d | t | |

| M16 | 16 | 45 | 40 | 10 | 20 | 11 | 28 | 16 | 40 | 32 | 17.5 | 2.5 |

| M20 | 20 | 45 | 40 | 12 | 20 | 11 | 32 | 20 | 36 | 46 | 22 | 2.5 |

| Material | Hot galvanized Q235 steel, 1C13(2Cr13)1C18Ni9Ti 0Cr17Ni12MO | 1C13(2Cr13)1C18Ni9Ti 0Cr17Ni12MO | Hot galvanized Q235 steel | |||||||||

As a professional cone rubber fender manufacturer in China, we provide not only supper cone fender, but also cylindrical rubber fender, wing type rubber fender, rubber corner packing, water expansion ring, and shipping facilities rubber sealed products.