SC marine fender is also called drum type fender, as it can be compressed into a drum-shape. It has the following advantages:

1. As compared with its counterparts, our high reaction force type rubber fender offers higher rated compression deformation, energy absorption and more.

| Type | Rated compression deformation | Reaction force (KN) | Energy absorption (KJ) |

| 1000H counterparts | 47.5 | 436 | 167 |

| TD-A1000H | 52.5 | 445 | 195 |

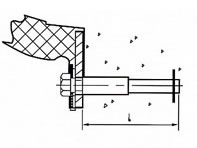

2. With an impingement plate at the head part, the supper cell rubber fender generates small reaction force on vessel body. According to customers' demands, the reaction force on vessel body can be 25 tons/m2 or less, making the marine fender ideal for large sized vessels.

3. With high energy absorption and reaction force, the SC marine fender is especially suitable for use on dolphin wharfs.

4. As compared with its counterparts, the supper cell rubber fender has smaller oblique compression deformation.

5. The PE veneer installed on the front of the impingement plate steel frame helps reduce the friction coefficient effectively.

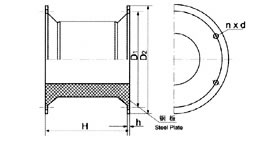

Specifications and Performance of Supper Cell Rubber Fender

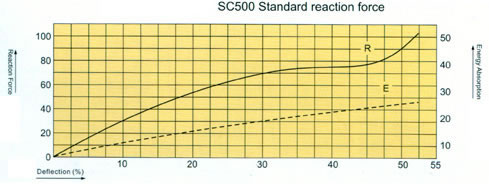

Performance of Supper Cell Rubber Fender

Note: Reaction=R Energy Absorption=E

Fittings for Super Cell Rubber Fender System

1. A list of fender fittings

2. Embedded parts and fasteners for the SC marine fender

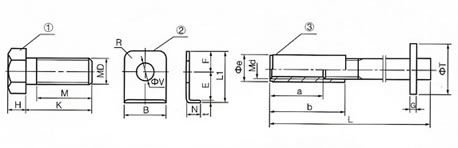

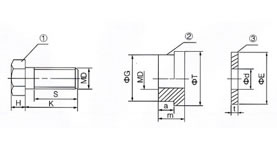

2.1 embedded bolt, nut and spacer

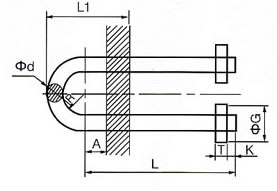

2.2 Embedded U type ring

2.3 Bolt, nut and spacer for veneer mounting

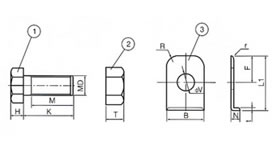

| Description / Size / Specification | Bolt | nut | Spacer | |||||||||

| D | K | S | H | m | a | G | D | T | E | d | t | |

| A630H-300H | 16 | 30 | 20 | 10 | 14 | 9 | 24 | 16 | 28 | 38 | 18 | 3 |

2.4 Bolt, nut and spacer for impingement plate mounting

| Material options | 1 | 2 | 3 | 4 |

| Q235 hot dip galvanization | 1Cr13(2Cr13) | 1Cr18Ni9Ti | 0Cr17Ni12MO |

3. The impingement plate of the supper cell marine rubber fender

3.1 The surface force acting across the external vessel body can be calculated according to: FP= R/(L×B)

In the above formula,

FP stands for surface force (kN/ m2).

L stands for the contact surface length (m) of the impingement plate.

B stands for the contact surface width (m) of the impingement plate.

R stands for the reaction force (kN) of the rubber fender system.

Hence, when the impingement plate length and width is given, the surface force can be achieved. When a specific surface force is given, we can easily get the desired impingement plate size.

However, while calculating the impingement plate size according to given surface pressure, please pay attention to the effective arrangement of veneers with the same specifications.

In addition, the impingement plate should be tailor-made according to the dock design, hydrologic condition, and the installation layout for the marine rubber fender system. Hence, customers can contact us for the impingement plate design.

2 1