Characteristics of Pneumatic Rubber Fender

1. Using compressed air for buffering, the pneumatic rubber fender deforms gently while being squeezed and pressed. It offers a large contact surface, low reaction force and large energy absorption.

2. When a ship is berthing at an angle, the pneumatic rubber fender can achieve oblique contact with the ship due to its unique structure, thus better protecting the ship and the dock.

3. The fender is floating on water all the time, allowing a ship to safely berthing at any time without influence from the rising and fall of tidewater and sea wave, etc. Meanwhile, floating on water ensures small friction force, which ensures no damage to ship's external coating and the rubber fender itself.

4. It is very easy for installation. Bolts and nuts are not required. The one thing we need to do is to use rope to tie the marine fender to the dock or the anchor post of a ship.

Applications of Pneumatic Rubber Fender

Typically, the pneumatic rubber fenders are tied to docks and ships to protect docks and ships from being damaged during berthing process. In addition, they can also be used as buoys, for pipe sealing and in the processing of transporting goods.

Types of Pneumatic Rubber Fender

A standard Hengsheng pneumatic rubber fender has no protective jacket and is in black color. The color is also customizable.

In order to prevent scratch damages to the fender, we can also offer different types of protective jacket for the rubber fender. There are three types of jackets available, as shown below.

Tire network type jacket is composed of several rubber tires which are connected with each other and tied tightly onto the pneumatic rubber fender. The two rings at the two ends of the fender can rotate flexibly. The fender with this type of jacket is suitable for large sized ships and vessels.

Rubber network type jacket is composed of special rubber pads and is also tightly tied onto the fender body. It expands and contracts flexibly when the fender is compressed. Pneumatic rubber fenders with this jacket is ideal for medium and small sized ships.

Cord network type jacket is weaved using nylon cords and the marine fender with this type of jacket is ideal for small sized vessels.

Structure

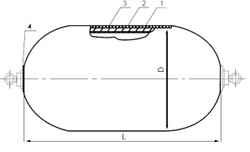

A standard pneumatic rubber fender is composed of four parts.

1. External rubber layer. It is used to protect the cord fabric layer and inner rubber layer, and has high tensile strength and wearing resistance.

2. Cord fabric layer. It is the reinforced layer of the pneumatic rubber fender. Its is twined using high strength cord fabric material.

3. Inner rubber layer. It functions to contain the compressed air and make sure there is no air leakage.

4. End flanges. It is the part where the air valve, embedded metallic parts and cord fabric layer are fixed together. It allows gas-filling and gas-discharging, and also allows the pneumatic rubber fender to be lifted.

1. External rubber layer 2. Cord fabric layer 3. Inner rubber layer 4. End flanges

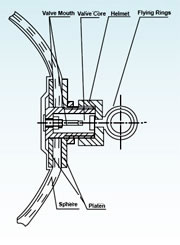

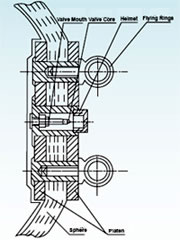

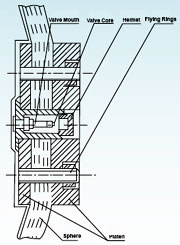

End Flange Structure

Specifications and Performance of Pneumatic Rubber Fender

The reaction force (R) and energy absorption (GEA) of the marine fender system when the rated compression deformation is 60%±5%.

| Specification(D×L) | Initial inflation pressure (Po) (0.05MPa) | Initial inflation pressure (Po) (0.08MPa) | ||||

| Weight (kg) | Reaction force (kN) | Energy absorption (KJ) | Weight (kg) | Reaction force (kN) | Energy absorption (KJ) | |

| 0.5×1.0 | 25 | 64 | 6 | 25 | 83 | 8 |

| 0.6×1.0 | 32 | 74 | 8 | 32 | 96 | 11 |

| 0.7×1.5 | 50 | 137 | 17 | 50 | 178 | 24 |

| 1.0×1.5 | 80 | 182 | 32 | 80 | 235 | 44 |

| 1.0×2.0 | 100 | 257 | 45 | 125 | 335 | 63 |

| 1.2×2.0 | 120 | 297 | 63 | 165 | 386 | 86 |

| 1.35×2.5 | 165 | 427 | 102 | 226 | 554 | 140 |

| 1.5×3.0 | 315 | 597 | 153 | 370 | 751 | 211 |

| 1.7×3.0 | 405 | 639 | 191 | 436 | 830 | 263 |

| 2.0×3.5 | 590 | 875 | 308 | 632 | 1138 | 424 |

| 2.5×4.0 | 1050 | 1381 | 663 | 1110 | 1815 | 925 |

| 2.5×5.0 | 1333 | 2019 | 943 | 1410 | 2653 | 1317 |

| 3.0×5.0 | 1880 | 2104 | 1210 | 215 | 2709 | 1571 |

| 3.0×6.0 | 2160 | 2583 | 1485 | 2470 | 3292 | 1888 |

| 3.3×4.5 | 2020 | 1884 | 1175 | 2300 | 2476 | 1640 |

| 3.3×6.0 | 2300 | 2783 | 1675 | 2600 | 3652 | 2338 |

| 3.3×6.5 | 2700 | 3015 | 1814 | 3080 | 3961 | 2532 |

Note: Weight on above chart refers to the weight of the pneumatic rubber fender excluding the jacket. The weight tolerance is ±10%, and reaction force tolerance is ±10%.

Hengsheng is a professional pneumatic rubber fender manufacturer in China. Our products include cylindrical rubber fender, shipside vertical rubber fender, supper cone fender, rubber corner packing, rubber gasket, shipping facilities rubber sealed products, and more.